Combustor coating slurries (up to 1100°C) can substitute energy and material intensive pack diffusion processes.

We offer slurries for chromizing and aluminizing treatments and pack processing materials.

Our masking materials Spritzschlicker and Topbond MO24 are extensively used to protect blade segments within aluminizing or chromizing pack processing.

Topbond-OX helps to protect TBC coatings from hot gas corrosion and spallation.

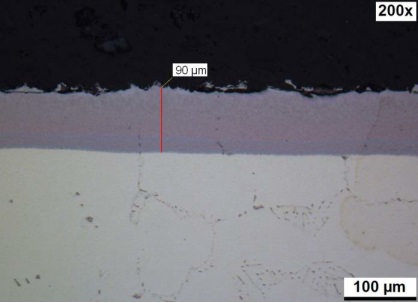

Diffusion coating: aluminization – cross section metallography.

Our quality engagement

M-M-Morant stands for high quality products. We are certified according to ISO 9001:2015. Our products are produced with incoming order and have a shelf life of 6 months.

Combustor/Turbine section slurries up to 1100°C

Diffusion chromizing slurries (up to 750°C)

Chromium (VI)-free (REACH compliant):

- MORANT C 45 GREEN

Diffusion aluminizing slurries (over 800°C)

Chromium (VI) version:

- CERAL 10

Chromium (VI)-free (REACH compliant):

- MORANT C 10 GREEN V2

Pack processing materials

- Chromium powder mixture

Masking materials for CVD/pack diffusion process

Basebond:

- Spritzschlicker SP 5/3

- Spritzschlicker SPP

Topbond (catcher/scavenger):

- Topbond MO 24

TBC protective coating

- Topbond – OX