Compressor coating materials (up to 600°C) comprise base- and topcoat materials.

The products can be combined to coating systems like CERAL 3450 and antifouling systems containing PTFE.

For quick local repair we offer touch-up systems like VPW-S1.

All products are available as chromium (VI)-free „GREEN“ version.

Our quality engagement

M-M-Morant stands for high quality products. We are certified according to ISO 9001:2015. Our products are produced with incoming order and have a shelf life of 6 months.

Compressor coating slurries up to 600 °C

Basecoat cathodic protection: Aluminium slurries

Chromium (VI) versions:

- CERAL 34

- CERAL 114

Chromium (VI)-free (REACH compliant):

- MORANT C 35 GREEN

- CERAL 34 GREEN

- CERAL 114 GREEN

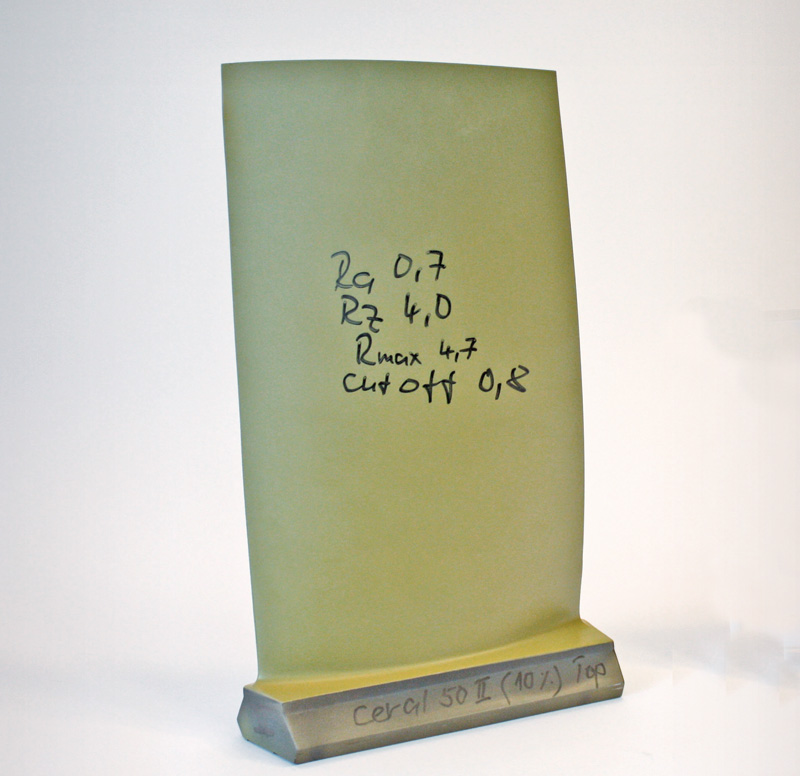

Topcoat

- CERAL 50 (unpigmented)

Pigmentation: khaki, blue, brown, green, customized

Chromium (VI)-free (REACH compliant):

- MORANT C 55 GREEN (unpigmented)

Pigmentation: khaki, blue, brown, green, customized

Coating systems

- Basecoat: CERAL 114

- Topcoat: CERAL 50

- Basecoat: CERAL 34

- Topcoat: CERAL 50

Chromium (VI)-free (REACH compliant):

- Basecoat: MORANT C 35 GREEN

- Topcoat: MORANT C 55 GREEN

Antifouling PTFE two-pack coating

- Basecoat: CERAL 34

- Topcoat: Lack VPW/PTFE

Chromium (VI)-free (REACH compliant):

- Basecoat: MORANT C 35 GREEN

- Topcoat: Lack VPW/PTFE GREEN

Touch-up for local repair

Chromium (VI)-free (REACH compliant):

- CERAL VPW S1